The domestic market price of methyl ethyl ketone (MEK) is showing a trend of regional convergence, with current prices at a low level for the year, reflecting that the market has not yet formed a clear directional trend amid the supply-demand game between supply and demand. Since June, major domestic suppliers such as the large plant in Huizhou, Guangdong, the large plant in Anhui, and the large plant in Zibo, Shandong, have collectively reduced production, leading to a sharp decline in supply. Changes in their operating rates have a significant impact on the market's supply-demand balance. Downstream industries of MEK, including pulp, leather, and adhesive sectors, are in their traditional low consumption season. Major pulp plants are maintaining production at planned volumes, while small and medium-sized factories are operating at low levels, keeping inventories at medium to low levels and primarily engaging in just-in-time replenishment. In mid-to-early June, after MEK prices fell to near cost levels, downstream users and traders entered the market to buy at low prices. Coupled with a concentrated release of overseas demand before the deadline for the U.S.'s global reciprocal tariffs, export orders for leading enterprises increased, alleviating supply pressure. However, after July 8, changes in tariff policies made it difficult for the strong export momentum to continue. Overall, the MEK market is at a critical juncture in the supply-demand tug-of-war, with prices fluctuating. Production reductions and maintenance on the supply side provide short-term support, but weak domestic demand and declining export competitiveness pose long-term pressures. Moving forward, it is essential to closely monitor the operating dynamics of leading enterprises, changes in raw material costs, and the pace of policy-driven favorable developments. The market is likely to continue its oscillating pattern amid the interplay of "weak realities and strong expectations."

Read More

Ethyl acetate in East China, affected by plant maintenance, some enterprises have slightly raised prices. In South China, the market is in a wait-and-see mood with insufficient demand support. In North China, tight supply has pushed up prices. Capacity utilization rate: Last week, the capacity utilization rate of ethyl acetate was 45.53%, down 1.64 percentage points from the previous week, mainly due to plant maintenance and weak demand. In 2025, 480,000 tons of new capacity is planned to be added, but the commissioning progress has been delayed by sluggish market conditions, with some plants postponing start-ups. Demand-wise, traditional sectors such as coatings and printing inks remain weak, with downstream procurement mainly based on rigid demand and high price sensitivity. Ethyl acetate exports continue to perform well, with single-month export volume in February 2025 hitting a ten-year high . The ethyl acetate market is characterized by regional differentiation, cost support, and weak demand coexisting. Prices have risen slightly, but the overall market still faces pressure from overcapacity, with exports serving as the main growth driver.

Read MoreThe domestic market price of methyl ethyl ketone (MEK) is showing a trend of regional convergence, with current prices at a low level for the year, reflecting that the market has not yet formed a clear directional trend amid the supply-demand game between supply and demand. Since June, major domestic suppliers such as the large plant in Huizhou, Guangdong, the large plant in Anhui, and the large plant in Zibo, Shandong, have collectively reduced production, leading to a sharp decline in supply. Changes in their operating rates have a significant impact on the market's supply-demand balance. Downstream industries of MEK, including pulp, leather, and adhesive sectors, are in their traditional low consumption season. Major pulp plants are maintaining production at planned volumes, while small and medium-sized factories are operating at low levels, keeping inventories at medium to low levels and primarily engaging in just-in-time replenishment. In mid-to-early June, after MEK prices fell to near cost levels, downstream users and traders entered the market to buy at low prices. Coupled with a concentrated release of overseas demand before the deadline for the U.S.'s global reciprocal tariffs, export orders for leading enterprises increased, alleviating supply pressure. However, after July 8, changes in tariff policies made it difficult for the strong export momentum to continue. Overall, the MEK market is at a critical juncture in the supply-demand tug-of-war, with prices fluctuating. Production reductions and maintenance on the supply side provide short-term support, but weak domestic demand and declining export competitiveness pose long-term pressures. Moving forward, it is essential to closely monitor the operating dynamics of leading enterprises, changes in raw material costs, and the pace of policy-driven favorable developments. The market is likely to continue its oscillating pattern amid the interplay of "weak realities and strong expectations."

Read More

Ethyl acetate in East China, affected by plant maintenance, some enterprises have slightly raised prices. In South China, the market is in a wait-and-see mood with insufficient demand support. In North China, tight supply has pushed up prices. Capacity utilization rate: Last week, the capacity utilization rate of ethyl acetate was 45.53%, down 1.64 percentage points from the previous week, mainly due to plant maintenance and weak demand. In 2025, 480,000 tons of new capacity is planned to be added, but the commissioning progress has been delayed by sluggish market conditions, with some plants postponing start-ups. Demand-wise, traditional sectors such as coatings and printing inks remain weak, with downstream procurement mainly based on rigid demand and high price sensitivity. Ethyl acetate exports continue to perform well, with single-month export volume in February 2025 hitting a ten-year high . The ethyl acetate market is characterized by regional differentiation, cost support, and weak demand coexisting. Prices have risen slightly, but the overall market still faces pressure from overcapacity, with exports serving as the main growth driver.

Read More

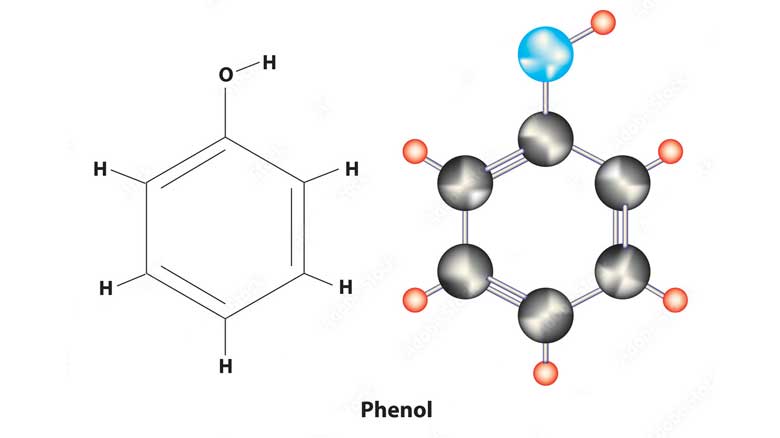

The domestic acetone market has shown a clear downward trend in prices. The global acetone market is influenced by weak demand in Europe and oversupply in Asia, with Saudi CP prices falling by $55 per ton, directly weighing on domestic market expectations. Although China's anti-dumping policy expired in June, imported supplies from Taiwan and South Korea have not significantly increased, and international low-priced cargoes continue to pressure the domestic market. The upstream pure benzene price has dropped sharply, with the average price of pure benzene in East China in the first half of 2025 declining by 22.62% year-on-year, weakening cost support for phenol. Despite phenol's relatively resilient pricing, the phenol-acetone industry remains near the breakeven line. Domestic phenol-acetone plant operating rates have stayed at 80%, and with the restart of Shenghong Petrochemical and Wanhua Chemical units, operating rates may rise to 90% in September. Acetone production increased from 270,000 tons in August to 300,000 tons, exacerbating supply-side pressures. While capacity utilization has improved, supply-demand imbalances persist. Weakness in downstream sectors such as real estate and automotive has slowed growth in major demand areas like bisphenol A and methyl methacrylate (MMA). Terminal solvent demand has slightly recovered as temperatures cool, but overall incremental growth remains limited. Traditional solvent demand remains stable, but slow growth in new applications (e.g., aliphatic water reducers) has failed to offset weakness in core demand sectors. Under the triple pressures of oversupply, falling costs, and weak demand, acetone prices continue to trend downward. Declines in upstream raw material prices have eroded cost support, while sluggish demand growth in downstream bisphenol A, MMA, and other industries, coupled with a surge in imports, has collectively pressured the market. In the short term, prices may remain weak and rangebound, but attention should be paid to potential impacts from pre-holiday stockpiling demand ahead of the two festivals and international market dynamics on supply-demand balance.

Read More

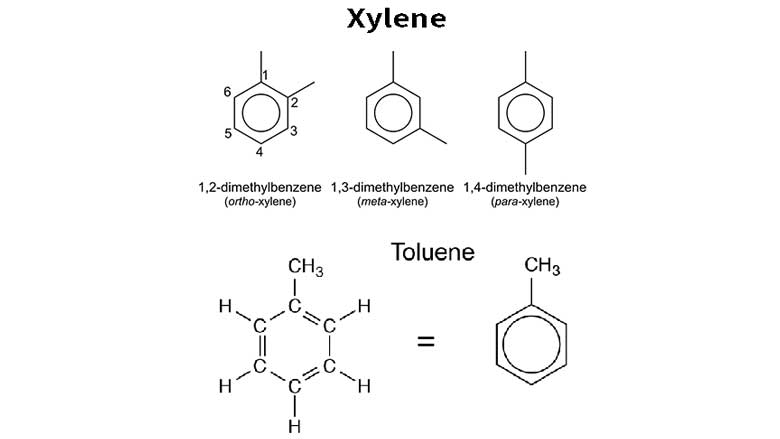

As of August 15, 2025, the aromatics product market exhibits characteristics of price differentiation and supply-demand dynamics. In the toluene market, East China region saw a 20 yuan/ton decrease compared to the previous trading day, with downstream procurement remaining need-based and trading sentiment remaining subdued. In the futures market, recent price volatility has intensified, with the August 14 closing price dropping 1.85% from the previous trading day, reflecting cautious market expectations regarding short-term supply and demand. In the xylene market, early morning spot prices in Jiangsu rose 30 yuan/ton compared to the previous trading day, indicating localized supply tightness. Summer gasoline blending demand provides price support for xylene, though gains are constrained by crude oil cost fluctuations. For pure benzene, prices are influenced by crude oil price volatility, environmental protection policies, and demand growth from the downstream PTA-PET. Driving factors: Pure benzene prices are jointly affected by crude oil price volatility, environmental protection policies, and demand growth from the downstream PTA-PET. From a supply-demand perspective, global mixed aromatics demand is projected to reach approximately 50 million tons in 2025, a 5% increase from 2024. Among this, Asian demand accounts for 60% of the global total, while North America and Europe account for 20% and 15%, respectively. China, as the world’s largest consumer of mixed aromatics, is expected to reach a consumption volume of 20 million tons in 2025, marking a 7% year-on-year increase. Global mixed aromatics production capacity is projected to reach 60 million tons in 2025, with China contributing 40%. However, due to stricter environmental protection policies and overcapacity issues, some small and medium-sized enterprises face elimination pressure. Statistics show that global mixed aromatics production is expected to reach 55 million tons in 2025, with China producing 22 million tons, a 3% year-on-year increase. It is noteworthy that a large-scale refining-chemical integration project in China will add 1 million tons of mixed aromatics production capacity upon commissioning in 2025, further optimizing market supply-demand dynamics. The current aromatics market is in a phase of price differentiation and supply-demand dynamics, with toluene under short-term pressure, xylene supported by blending demand, and pure benzene showing long-term bullish potential. Close attention should still be paid to external market dynamics, maintaining a cautious operational mindset.

Read More

Hi everyone, today I want to talk to you about the risks of acetone. Acetone is a common organic solvent that is widely used in many fields, such as cosmetics, furniture manufacturing, and printing. However, we should also be alert to the potential risks of acetone. First, acetone is volatile and it releases toxic gases. If exposed to high concentrations of acetone gas for a long time, it may pose a potential threat to our health. The volatility of acetone also means that proper measures need to be taken during storage and use, and good ventilation should be maintained to avoid exposure to high concentrations of acetone gas. Secondly, acetone is a flammable substance with a low flash point. It may burn as long as it comes into contact with open flames or high temperatures. Therefore, be sure to stay safe when using acetone. It is forbidden to store acetone near flammable materials and keep it away from open flames and high-temperature sources. In addition, long-term exposure to acetone may cause some health problems. Acetone irritates the skin and eyes, which may cause dryness, itching, or redness, and even cause eye pain and blurred vision. Therefore, after contact with acetone, wash your skin and eyes immediately and seek medical help. Finally, acetone also has certain ecological risks. If not properly handled, acetone may enter the soil and water, causing potential harm to the ecosystem. Therefore, when using acetone, be sure to pay attention to environmental protection and properly handle and dispose of waste. Hope that through the sharing, I can remind everyone to be vigilant about the risks of acetone.

Read More

Butyl Acrylate is a chemical compound with the formula C7H12O2 and is commonly known as butyl ester of acrylic acid. It is a colorless liquid with a fruity odor. Butyl acrylate has various applications in different industries due to its unique chemical properties. Here are some of the primary uses of butyl acrylate: 1. Coatings and Paints: Butyl acrylate is primarily used as a raw material in the production of water-based coatings and paints. It is a key component in acrylic emulsion polymers, which provide excellent adhesion, flexibility, and weather resistance. 2. Adhesives: Butyl acrylate is used in the manufacturing of pressure-sensitive adhesives (PSAs). These adhesives are commonly used in tapes, labels, and other adhesive applications that require quick and strong bonding. 3. Textile Finishing: Butyl acrylate is employed in the textile industry as a finishing agent for fabric. It enhances the fabric’s strength, wrinkle resistance, and dye receptivity. 4. Paper Coatings: Butyl acrylate is used in the production of paper coatings, which provide enhanced printability, smoothness, and water resistance to paper products like magazines, catalogs, and packaging materials. 5. Emulsion Polymers: Butyl acrylate is a key component for the production of emulsion polymers used in various applications such as carpet backing, non-woven textiles, and construction materials. 6. Plastic Additives: Butyl acrylate is utilized as an additive in plastic formulations to improve impact resistance, flexibility, and weatherability. It is commonly incorporated into PVC, acrylic, and other plastic products. 7. Personal Care Products: Butyl acrylate is used in the production of personal care products such as hair sprays, nail polishes, and cosmetics, where its film-forming properties and adhesion are beneficial. If you need solvents like Butanone, Toluene, Xylene, Isopropanol, Styrene, Cyclohexanone, Ethanol, Methanol, Ethyl Acetate, N-butyl Acetate, Butyl Acrylate, etc., mainly used in paints, coatings, spray paints, printing, leather, ink, and pharmaceutical intermediates. You can contact Batong Chemical Group.

Read More

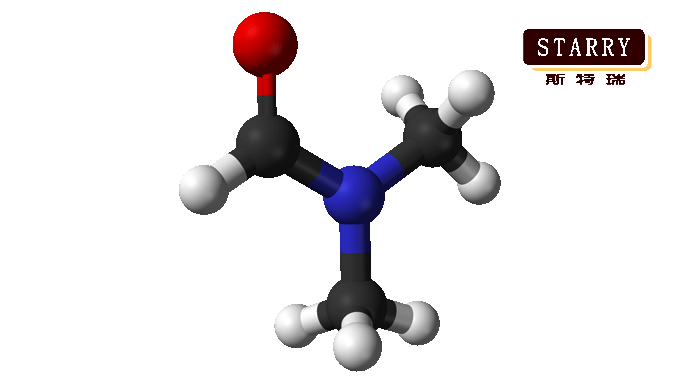

N, N-Dimethylformamide (DMF) is a versatile organic solvent with a wide range of applications in various industries. Here are some of the main uses of DMF: 1. Chemical Reactions: DMF is commonly used as a solvent in chemical reactions. It can dissolve a wide range of organic and inorganic compounds and is particularly useful for reactions involving polar and nonpolar compounds. 2. Pharmaceutical Industry: DMF is widely used as a solvent in the pharmaceutical industry for drug synthesis, formulation, and purification processes. It aids in dissolving and stabilizing various drug compounds. 3. Polymer Industry: DMF serves as a solvent and reaction medium in polymer synthesis, including the production of polyurethanes, polyamides, and polyacrylonitrile. It helps in dissolving and dispersing polymer precursors and facilitates the formation of homogeneous polymer solutions. 4. Electronics: DMF is used in the electronics industry as a solvent for cleaning, degreasing, and removing soldering residues from electronic components. It is also used in the production of electronic devices, such as semiconductors and printed circuit boards. 5. Textile Industry: DMF is employed as a solvent in the dyeing and finishing of textiles. It helps in dissolving and dispersing dyes, improving color uniformity and dye penetration into the fabric. 6. Adhesives and Sealants: DMF is used as a solvent in the formulation of adhesives and sealants. Its high solvency power allows for the dissolution of various adhesive components, enabling proper mixing and application. 7. Metal Processing: DMF is utilized in metal processing industries as a solvent for metal cleaning, degreasing, and electroplating processes. It helps in removing dirt, oils, and contaminants from metal surfaces. If you need solvents like Butanone, Toluene, Xylene, Isopropanol, Styrene, Cyclohexanone, Ethanol, Methanol, Ethyl Acetate, N-butyl Acetate, Butyl Acrylate, etc., mainly used in paints, coatings, spray paints, printing, leather, ink, and pharmaceutical intermediates. You can contact Batong Chemical Group

Read More

Phenol is a compound with antibacterial, anti-inflammatory, analgesic, and other effects. 1. phenol has strong antibacterial and anti-inflammatory effects, can kill various bacteria, fungi, and viruses, and effectively prevent and treat infectious diseases. 2. Phenol can relieve pain and discomfort by inhibiting pain transmission and reducing tissue inflammation and has a certain relief effect on mild pain symptoms such as headache, toothache, and joint pain. 3. Phenol has a certain antioxidant effect, which can prevent the damage of free radicals to body cells and delay the aging process. It should be noted that phenol is toxic at high concentrations, should be used in accordance with the dosage prescribed by the doctor or the instruction manual, and should not be abused at will. It should be used with caution for sensitive groups and pregnant women. It should be noted that phenol is toxic at high concentrations, should be used in accordance with the dosage prescribed by the doctor or the instruction manual, and should not be abused at will. It should be used with caution for sensitive groups and pregnant women.

Read More

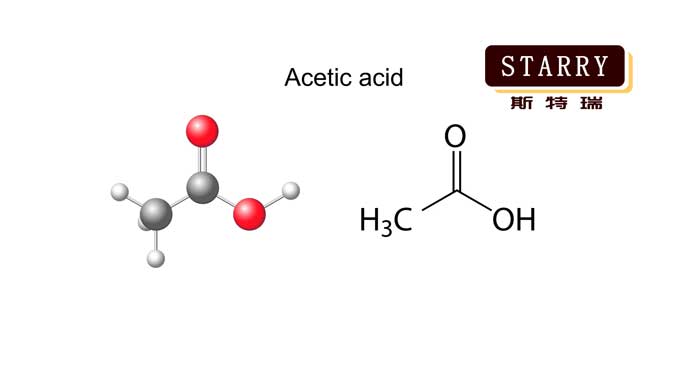

Acetic acid, also known as ethanoic acid, is a colorless liquid organic compound with a distinctive sour taste and pungent smell. It has a wide range of applications in various industries. Here are some of the main uses of acetic acid: 1. Vinegar Production: Acetic acid is the main component of vinegar, making up about 4-18% of its content. It gives vinegar its characteristic taste and smell. 2. Chemical Production: Acetic acid is used in the production of a number of chemical compounds. For example, it is used to produce vinyl acetate monomer (VAM), which is used in the manufacture of polymers for adhesives, paints, and films. 3. Food Industry: Acetic acid is used as a food additive and preservative. It helps to prevent the growth of harmful bacteria in food. 4. Textile Industry: Acetic acid is used in the dyeing and finishing processes of the textile industry. It helps to promote color retention and fabric strength. 5. Pharmaceutical Industry: Acetic acid is used in the production of certain medications, including aspirin and other pain relievers. 6. Cleaning Products: Acetic acid is used in a variety of cleaning products due to its ability to cut through grease and remove mineral deposits. 7. Photography: Acetic acid is used as a stop bath in photography. The acid halts the development process and prevents the image from changing further. Please note that acetic acid can be corrosive and should be handled with care. Always follow safety guidelines when using products containing acetic acid.

Read More

Methyl Ethyl Ketone (MEK) and Acetone are both solvents used in various industries. They share some similarities but also have distinctive differences. Here are some of them: 1. Structure: The fundamental difference lies in their chemical structure. MEK consists of four carbon, eight hydrogen, and one oxygen atom, while Acetone consists of three carbon, six hydrogen, and one oxygen atom. 2. Strength: MEK is a stronger solvent than Acetone. It takes longer to evaporate and is often used for tasks that require a slower evaporation rate. 3. Application: Because of its stronger nature, MEK is often used in industrial applications such as in the manufacture of plastics, and textiles, and in the creation of paraffin wax. On the other hand, Acetone is commonly used as a nail polish remover in laboratories. 4. Safety: Both are flammable and have strong odors, but Acetone is generally considered safer and less damaging to the environment. 5. Cost: Acetone is usually cheaper than MEK. Remember, both substances should be used with care, as they can be harmful if mishandled. Always follow safety guidelines when using these chemicals.

Read More